EASTEY PNEUMATIC L-SEALERS

Professional Series Pneumatic L-Sealers

EASTEY’s Professional Series ESA L-Sealers provide top of the line features and the most robust L-Sealer design on the market today. Expertly welded from ¼” cold rolled steel, EASTEY Professional ESA L-Sealers will withstand even the most abusive real world sealing applications. As a measure of strength, EASTEY L-Sealers weigh nearly twice as much as competitive models.

Eastey L-Sealers are designed and built to give you all the performance features needed for positive sealing a wide variety of films including polyolefin, polyethylene, and PVC. Cast seal arms, pneumatic operation, stainless steel film clamps, and heavy-duty magnet clamping are just some of the features that provide the durability you have come to rely on from EASTEY. See for yourself why EASTEY has been a leader in the shrink packaging industry for over 25 years.

- Designed to seal most polyolefin, polyethylene, and PVC* shrink films

- All-welded main frame from ¼” cold rolled steel

- Built-in drawer for tools or spare parts

- Seal head casting equipped with head return cylinder

- Stainless steel film clamps hold film in place while sealing

- Dual palm pneumatic seal head activation

- Hot knife seal systems available with mushroom (standard), pancake, or arrow inserts

- Dual locking magnet clamps apply even pressure across seal bar

- Adjustable dwell time for better seal control

- Solid state temperature control adjustable for a variety of films

- Adjustable product tray accommodates wide variety of product sizes

- Takeaway conveyor can be raised or lowered to center-seal product

- Automatic takeaway conveyor

- Heavy duty film cradle allows for easy changeovers and adjustments

- Adjustable pin perforator provides air evacuation

- Side seal size from 20” – 50”; front seal size from 16” – 100”

- Maximum film width up to 44”

- Maximum film roll OD up to 12”; 10” with power unwind

- Custom two-part epoxy finish resists scratching

- Heavy duty casters for transportation within plant

- Available in 110v, 220v, or optional 480v

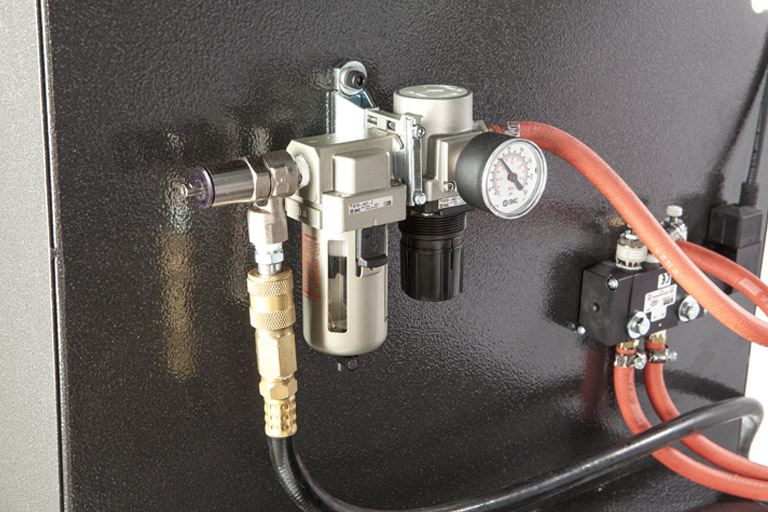

- 60-80 psi air requirement

- Easy to use design requires minimal training and maintenance

- Made in the USA

*With Hot knife systems only

Power Film Unwind – Allows free feeding of film increasing operator efficiency

Film Inverter – Inverting head allows the film to come off the back of machine. This pre-opens the film and minimizes operator effort which in turn increases output

Hot Knife Inserts – Hot knife inserts available in Mushroom, Pancake, or Arrow styles

Specialty Models – Stainless steel and left hand models available

DuoSeal – Continuously Heated Seal Bar