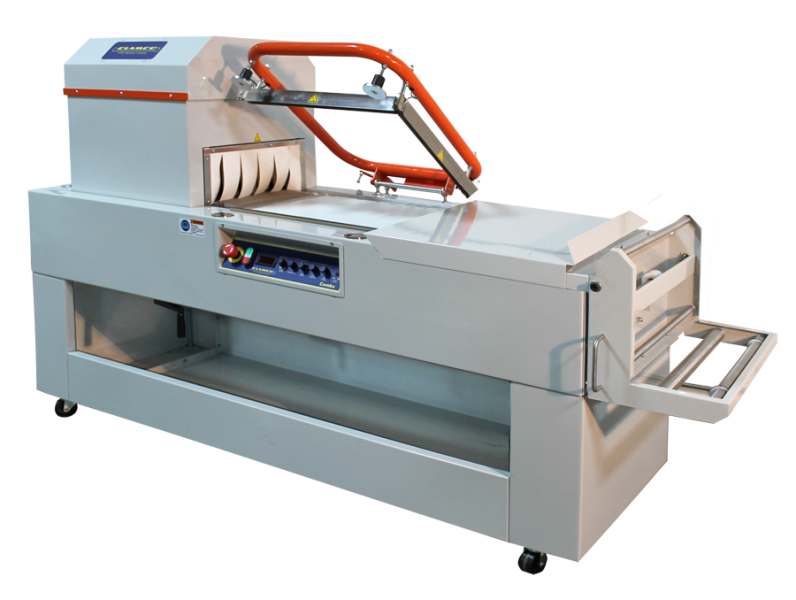

Clamco Dem 2 Combo Shrink Wrap Machine

Combo Shrink Wrap Machine Overview

Get professional packaging results with the Clamco Dem 2 Combo, an easy to use, dependable, low maintenance combination L-bar sealer and shrink tunnel. Sporting several key features, the Dem 2 Combo shrink wrapping machine is ideal for high production environments.

The Dem 2 Combo shrink wrap machine can seal a wide range of package sizes with its 21” long side seal and 18” long end seal. The standard tunnel opening is 6” tall by 15” wide, with 1” of clearance inside the tunnel for packing products that are up to 6” high. An optional 9” high tunnel opening is available for taller products.

The Dem 2 shrink wrapper is a model of power and efficiency. Though it has a powerful 4,000 watt tunnel, the Dem 2 runs on 220 single phase power, requiring only a 20 amp service. When not in active use, the tunnel goes into green mode, slowing down the conveyor to minimize heat loss. As soon as the seal bar is used, the conveyor returns to the speed set by the operator.

This dependable combination L-bar sealer and shrink tunnel uses time-proven components in a modern design. The Clamco Dem 2 Combo shrink wrapper is built for ease of use and consistent production.

More Shrink Tunnel Power

A precise digital tunnel temperature controller in conjunction with 4,000 watts of heating power and a heavy-duty tunnel blower that provides 360° air circulation for superior consistency and maximum performance. 1.62 watts / cubic inch of tunnel volume provides the power to keep up with high volume production while maintaining tunnel temperature.

Better L-Bar Sealer Consistency

The Dem 2 Combo shrink wrap system produces consistently strong seals using a heavy-duty dual magnetic hold down. This mechanism ensures consistent seal pressure, seal after seal, down the full length of the seal bar, using a variety of film types and sizes.

Improved Shrink Packaging Ergonomics

The Dem 2 Combo shrink wrap machine features a single-plane adjustable height product path to provide smooth product transfer. Loading and positioning film is a snap with a unitized package tray and film cradle designed for easier positioning of the product on the film. The large diameter tubular seal bar arm allows for a variety of comfortable operator grip positions, reducing fatigue and repetitive motion issues.

User Benefits:

- Film cradle is end-mounted and unobstructed for fast film loading

- Film cradle slides smoothly and locks in place to accommodate different film widths and product sizes

- Easy to reach, low effort crank to adjust seal bed height for seal centering

- Easy to use controls with large digital tunnel temperature display

- Tubular seal bar arm is comfortable to grip, and the two magnets do the work of applying pressure to the seal, reducing operator fatigue

Operating Benefits:

- Magnetic seal bar hold down and a power take-away conveyor (optional) allows the operator to prepare the next package before the end of the cycle

- Single-plane product path ensures products are transferred smoothly from the sealer to the tunnel

- Quick replace seal wire via a single assembly

Set-Up Benefits:

- Simple controls minimize training and ramp-up time with new operators

- Comes standard with a stand and casters, to support multiple workstations

- Plug in the electrical cord and you’re ready to start packaging, no air required

Service Benefits:

- Power take-away conveyor is easy to remove and service

- Control panel electronics are accessible via ¼ turn fasteners

- Tunnel adjustments can be made by removing cover plate

Safety Benefits:

- Prominent emergency stop button ceases all heating and conveyor movement

- Stainless steel film clamps envelop the seal wire, keeping the operator from inadvertently coming in contact with the wire

- Impulse sealing system heats and then cools and trims the seal, so wire is not hot when seal bar opens.

Technical SpecsDem 2 ComboSeal length (end)18?Seal length (side)21?Film width (max)22?Tunnel opening width15?Tunnel opening height (standard / optional)6? / 9?Tunnel inside height (standard / optional)7? / 10?Tunnel inside length25?Tunnel power (watt)4,000Power take-away conveyorOptional

Options

- Power take-away conveyor for automatically transporting the product from the seal area to the heat tunnel

- 9” high tunnel opening for large products

- Exit Conveyor

- 74” long frame (89” standard) for smaller production environments