BB-2/SS Stainless Steel Bottom Belt Case Taper

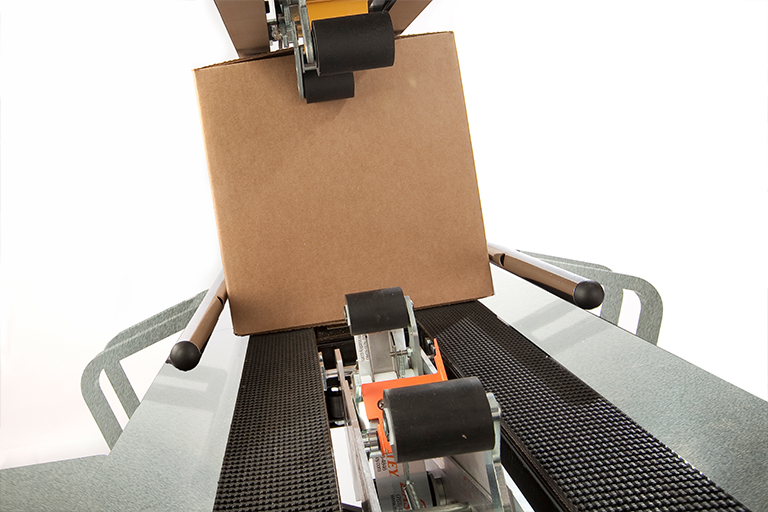

Eastey’s BB-2/SS case taper is a cost-effective top and bottom case taper designed for large run case sealing. BB-2/SS utilizes pressure-sensitive tape and features self-centering side rails, a rugged bottom belt drive, and heavy-duty mast that easily adjusts to handle a variety of case sizes. BB-2/SS is ideal for washdown conditions.

BB-2/SS offers the durability, versatility and reliability that you have come to rely on from Eastey. The system’s unique and simple design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum and providing fast and efficient alternatives to hand taping.

BB-2/SS offers fast and easy case changes with adjustable side rails and flexibility ranging from 4.5? to infinite box length. BB-2/SS is also able to seal cases ranging from 4.5? to 22.5? in width, as well as 4? to 25.5? in depth. Adjustments can be made on the fly with easy hand tighten knobs on a single mast design. A single drive motor and aggressive drive belts will move your boxes and stand up to your toughest challenges. BB-2/SS is also perfect for integration with ink jet printers where coding is required on boxes.

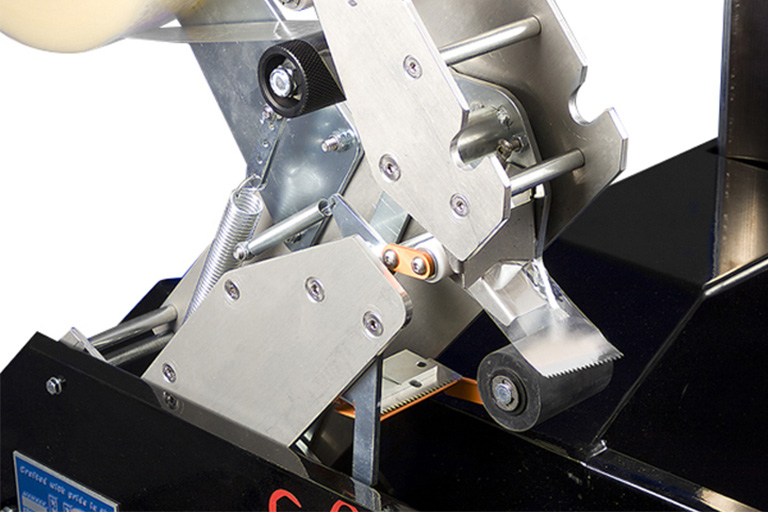

Top and bottom tape heads are interchangeable and tip back for easy threading.

Industrial strength drive belts move boxes consistently through the taper.

Minimum Box Size – 4.5? (Length) 4.5? (Width) 4? (Depth)

Maximum Box Size – infinite (Length) 22.5? (Width) 25.5? (Depth)

- Plug-in and go operation

- 12 gauge stainless steel

- Interchangeable top and bottom tape cartridges

- Adjustable side rails

- Industrial strength drive belts

- Easy hand-tighten adjustments

- Safe single mast design

- No air required

- Low maintenance

- Simple integration with ink jet printers

- Washdown motor and electronics

Sealer Type – Stainless steel bottom belt, top and bottom case sealer

Machinery Makeup – Industrial strength 12 gauge stainless steel

Belt Speed – 60 feet/per minute

Tape Speed – 30 cases/per minute, depending on box size and operator efficiency

Adjustable Side Rails – Palm grip knobs offer quick and simple adjustments

Height Adjustment – Standard adjustable legs for 22.25” to 34.25 conveyor heights

Tape Size – 2” wide pressure sensitive tape, up to 15” diameter rolls, optional 3” wide tape

Tape Cartridge – Proven design requires no lubrication, tips back for simple tape threading, removable for maintenance and interchangeable with top or bottom cartridges

Air Requirements – None

Electrical Requirements – 110 VAC, 60Hz, 10A

3” Tape Head – Accepts 3” wide tape rolls

Casters – Rugged wheels for transportation within plant

Front and Rear Packing Table – Solid tables bolt before and/or after taping system to allow for case packing

Top Squeezers – Allows for operation with variable speed conveyors