Eastey EB35A EB50A EB70A Professional Sleeve Wrapper

RELIABLE MANUAL BUNDLING

EASTEY’S automatic bundler’s offers the reliability needed to provide a “bull’s-eye or natural closure” on trays, individual or multi-packed products.

Professional Series Automatic Bundler EB35A EB50A EB70A

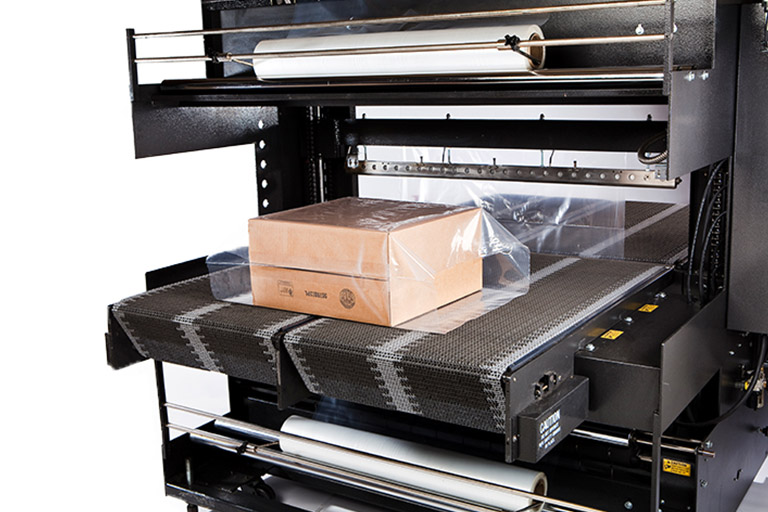

Proven reliable over and over again, EASTEY’s automatic bundler provides you with all the quality features found in much higher priced machines. They are designed and built to give you all the features needed for positive sealing of polyethylene film.

EASTEY’S automatic bundler’s are expertly welded on 1/4” cold rolled steel frames and designed to handle the day to day abuse of even the most demanding bundling applications. Each bundler utilizes two rolls of single wound film mounted on the same side of the machine and an upper and lower power film unwind for ease of use. See for yourself why EASTEY has been a leader in the shrink packaging industry for over 25 years.

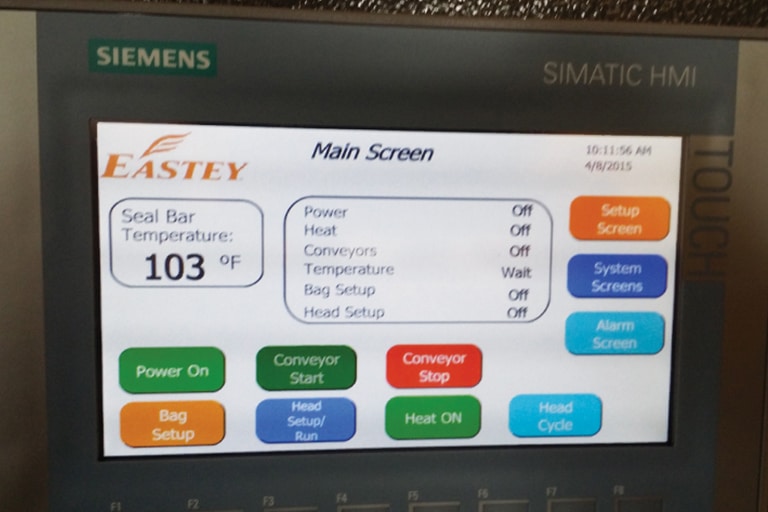

Color PLC touchscreen can be password protected if needed.

Easy to use control panel lets users adjust dwell time and temperature settings for their specific application.

Exit conveyor transfers the package into a recommended Eastey shrink bundling tunnel to produce a very tight and secure package.

35”, 50”, & 70”, hot knife seal system ensures a clean, positive, and even seal every time.

- Designed to seal most polyolefin, polyethylene, and PVC shrink films

- 35”, 50”, and 70” wide hot knife seal system

- Upper and lower powered film unwind for smooth feed of film

- All-welded main frame from 12 gauge steel

- 22” adjustable product pass through height

- Bases supplied with locking casters for easy transport

- Pneumatic product pusher with adjustable return stroke lengths

- Self center seal system

- Automatic seal system with magnetic hold for consistent proper seal

- Self tracking conveyor belt and product indexing

- Leveling legs to provide study base

- PLC touchscreen operation for easy operation adjustments

- Flexibility for fully automatic or single product operation

- Durable custom two-part epoxy finish resists scratching

- 220v standard. Optional 480V

- 70” max film width

- 14” max film OD

- Easy to use design requires minimal training, maintenance, and trouble free operation