Clamco R3200 Fulfillment Bagger

Increase efficiency and lower material costs

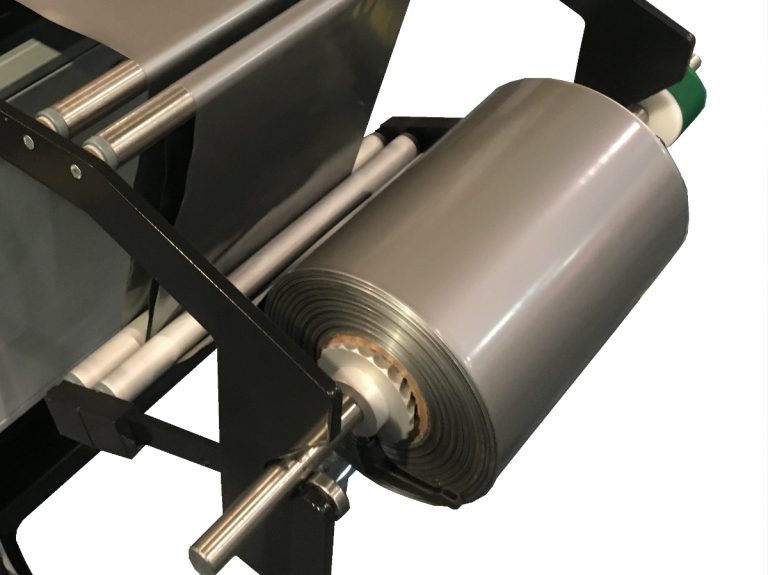

The Rollbag™ R3200 Fulfillment automatic bagger is an elite mail order fulfillment bagging system. This automatic bagger works with poly tubing as well as bags on a roll. The benefits of poly tubing include lower material costs as well as right-sizing of the bag to the product by changing bag length on the fly, lowering shipping costs.

The Rollbag R3200 Fulfillment bagger is equipped with a label printer applicator, for next bag out printing, to create a fully integrated order fulfillment bagging solution. Furthermore, this bagger can be equipped with a TwinPrint® dual sided label printer applicator to include the shipping information and packing slip on a single label. For those with long enough bags, a thermal transfer printer option is also available, allowing you to print directly on the bag material.

The standard Rollbag R3200 works with bags up to 16? wide x 24? long and has a seal bar opening of up to 6? (8? opening optional). The larger Rollbag R3200XL Fulfillment works with bags up to 22? wide x 36? long and features a seal bar opening of up to 11?.

The Rollbag R3200 Fulfillment bagger includes a 1-year limited warranty, extendable up to 5-years when exclusively using Rollbag brand bags on a roll or poly tubing!

This bagger is ideal for e-commerce, order fulfillment, e-tail, and distribution facilities that require the highest level of performance in their order fulfillment packaging operation.

Printing Options

- TwinPrint® dual sided label printer applicator to include the shipping information and packing slip on a single label

- Print Registration – for use with pre-printed poly tubing that uses registered print film

Safety Options

- Dual Touch Start Switches – two switches must be touched simultaneously in order for the machine to cycle

- Light Curtain – prevents the operation of the bagger when the optical detection field is obstructed

Other Options

- Foot switch activation instead of using start button

- Adjustable Hole Punch – pneumatic punch that puts a small perforated hole in the bag, allowing for excess air to escape

- End of Roll Detector – used to monitor when the end of a roll has been reached

- Tall Frame – bag lengths over 24”

- Right to left package outfeed

Operating Benefits

- Works with poly tubing as well as pre-opened bags on a roll

- Lower material cost when using poly tubing, by making bags inline before they are filled and sealed

- Color touchscreen is operator friendly and has clear readable prompts and alarms

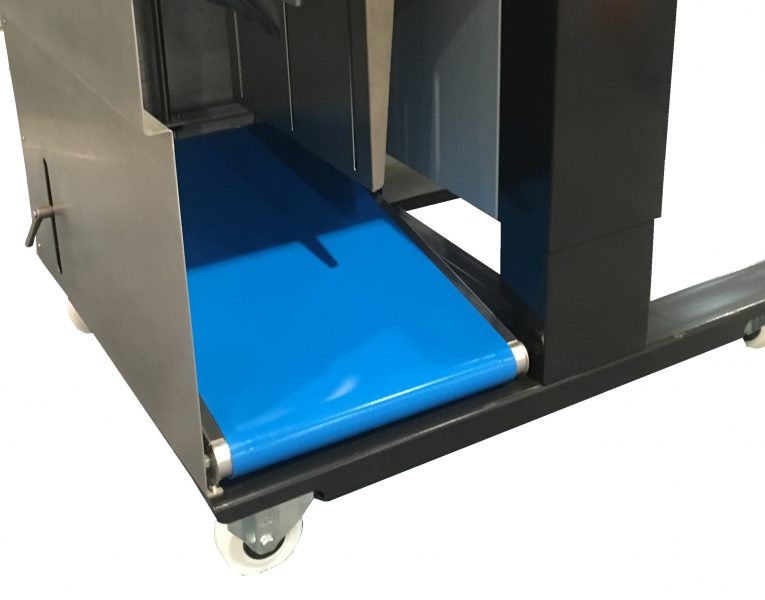

- Integrated package discharge conveyor which allows bags to be transported to the right (standard), left (optional), or back underneath the machine (optional).

- Large diameter rolls and variable bag length enables machine to package products of practically any length

- Easy load bag opener squares the bag up for ease of loading and supporting heavier products

- Bag open sensor detects that the bag is in position and ready to accept product

- Integrated label printer applicator ties into warehouse management system to print shipping label directly on the outside of the bag

Set-Up Benefits

- Interface ports to integrate robotics and other feeding systems

- When using poly tubing, change bag length on the fly, manually or automatically via integration to WMS

- Store different bag length settings for quick job set-up

- Stand with casters and a compact design provides portability

- Quick roll change to facilitate easy and fast changeover

Maintenance Benefits

- Designed to minimize preventative maintenance costs by using off-the-shelf components

- Self-diagnostics ensure quick problem solving

- Label applicator uses direct thermal printing, eliminating the need for costly thermal transfer printer ribbon

- Warranty extendable up to 5 years when exclusively using Rollbag brand material and labels

Safety Benefits

- Low-pressure closing with obstruction detection system for improved operator safety

- Designed to meet CE requirements for improved safety and troubleshooting

Model Rollbag R3200 Fulfillment Rollbag R3200XL Fulfillment Speed (bags)up to 40/min up to 40/min Speed (poly tubing)up to 20/min up to 20/min Feed rate up to 40”/sec up to 40”/sec Max bag width16”22?Max bag length24?36?Bag thickness1–5 mil1–5 milElectrical120V @ 20A120V @ 20AAir80psi @ 5CFM80psi @ 5CFMWarranty1 year,

extendable up to 5 years1 year,

extendable up to 5 years Dimensions

(W x D x H)47” x 44” x 48”56? x 60? x 48?* Speed is dependent upon bag size, thickness, product, and printing