Clamco R1285 Velocity Poly Mailer Roll Bagger For Fullfillment

High speed printing and bagging

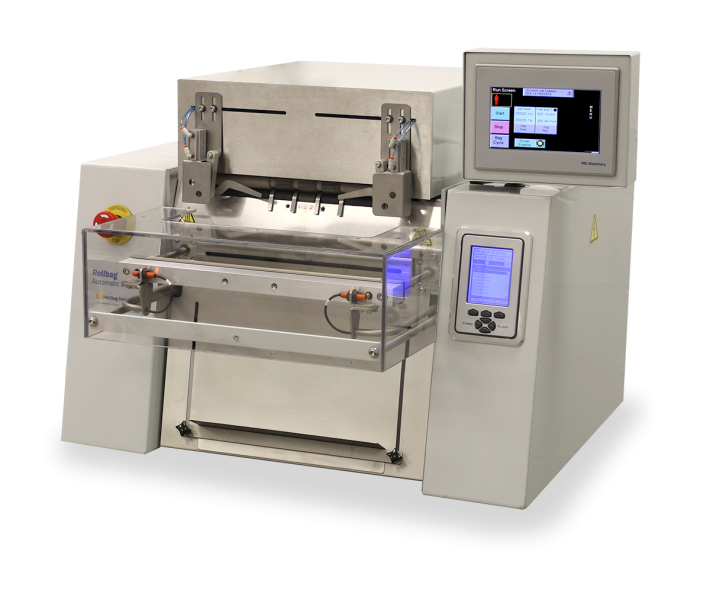

The Rollbag R1285 Velocity automatic bagger is the fastest tabletop poly mailer packaging system on the market for mail order fulfillment packaging.

Equipped with a reliable 4? thermal transfer printer (203 dpi), the R1285 Velocity bagger is designed for “next-bag-out” printing—perfect for efficient mail order fulfillment packaging using poly mailers. The next-bag-out printing feature enables the packer to scan a packing list and print the corresponding shipping label on the next bag that is disbursed from the bagger. The thermal printer provides a broad range of connectivity to meet diverse application requirements and easily integrates into any warehouse management system.

High performance in a small footprint

The R1285 Velocity automatic bagger is designed to work with plain or custom printed pre-opened bags on a roll and coex poly mailers up to 11? wide. Because the R1285 Velocity bagger uses compressed air, you get the same performance as larger floor standing mail order fulfillment bagging systems, in a much smaller package. This results in an automatic bagger that is ideal for multi-shift use in industrial environments.

Unlike other baggers in this category, the R1285 Velocity can be equipped with a broad range of options to custom tailor the system to your poly mailer packaging process. It even has a 7? HMI touchscreen interface that is easy for people of all skill levels to operate.

Extended warranty

The Rollbag R1285 Velocity includes a 1 year limited warranty, that can be extended up to 5 years when exclusively using Rollbag brand poly mailers and thermal transfer printer ribbon in your mail order fulfillment bagging operation.

- Air Expeller / Bag Deflator

This option mounts to the pressure bar and compresses the air out of the bag as it travels inward toward the machine just prior to the sealing process.. - Additional Parts Funnels

Wide variety of standard and custom funnels to assist product handling - Articulating Bag Support

A pneumatically operated shelf that is used to support the bottom and back of the bag during the loading process. The shelf then tips down and out of the way after the bag has been sealed. - Bag Spreader / Seal Flatteners

Pneumatically operated opposing fingers that pull each side of the bag taught above the seal area to flatten the bag seal area; thus, decreasing the possibility of wrinkles in the seal area and increasing seal integrity. - Bag Support

Fixed shelf to support bag during loading of heavy products - Dual Start Buttons(Anti-Tie Down)

Two optical no touch” buttons must be passed through simultaneously to initiate the cycle operation of the bagger. If the two sensors are not passed through at the same time, the bagger will not cycle ensuring that fingers or hands cannot be in the seal area. Recommended for hand load applications where no funnel is used. - Ergonomic Start Switch

A pass-through switch used in place of a foot pedal to cycle the machine - Conveyor / Feeder Ready Cabling

The pre-wired cables that allow you to connect to the DC controls of in-feed devices - Kit/Counting Conveyors help with kit packaging and/or product counting operations

- Tabletop Console Stand

Mechanically adjustable stand for all the tabletop machines - 220 Volt Option Is available 220V, 50/60 Hz

Operating Benefits

- 7” color touchscreen with clear readable prompts and alarms

- Electric foot switch, photo-eye (optional), or fully automatic cycle start

- Includes load shelf with bag support (up to 13” bag length)

Printing Benefits

- High-resolution reliable printing performance for 24/7 operation

- Large graphic display for quick navigation and printer notifications

- Broad range of connectivity for use with applications and networks

Maintenance Benefits

- Off the shelf modular components for easy replacement

- Self-diagnostics ensure quick problem solving

- Reliable components designed for multi-shift production

Set-Up Benefits

- Utilizes Rollbag pre-opened bags-on-a-roll for quick bag size changes and easy set-up

- PLC with 20 job storage, batch counters, packaging statistics & temperature control

- Built-in interface ports integrate counters, scales, and robotics

Safety Benefits

- Low-pressure seal bar closing with obstruction detection

- Dual palm buttons for added operator safety (optional)

Model Rollbag R1285 Velocity Bagge rSpeed Up to 60 bags per minute (dry cycle, no print)Bag Width2? – 11?Bag Length4? – 20?Bag Thickness1 – 5milSeal Width1/8?Printer4? integrated thermal transfer @ 203 dpi Electrical Requirement120V, 7A, 50/60HzAir Requirement80psi @ 2 – 5CFMDimensions30?W x 30?D x 24?HWeight85 lbsWarranty1 year, extendable to 5 years when exclusively using Rollbag brand material Origin Made in the USA